Initiatives

Aligned subcontractors

We continue to focus on developing collaborative, long- term relationships with our supply chain partners through our Advantage through Alignment (AtA) programme.

AtA is designed to enable deep collaboration and provide support to Aligned subcontractors through training and education, by sharing our working practices, values and our vision and by giving access to our behavioural safety programme, Challenging Beliefs, Affecting Behaviour, BIM training and Continuing Professional Development.

During the year, our core trades spend with Aligned subcontractors was 61% (2023: 58%).

Prompt payment

As a signatory of the Prompt Payment Code, we are committed to paying 95% of supply chain invoices within 60 days. We continue to outperform this target, with 96% of invoices paid within 60 days in the year to 30 June 2024 (2023: 98.1%) and the average days to pay remains low at 26 days (2023: 26 days).

The implementation of a new ERP system during 2024, had a short-term negative impact on performance, including against the target of paying 95% of invoices from suppliers with fewer than 50 employees within 30 days, with 79% paid within 30 days (2023: 88%). We expect this metric to improve again in the next financial year.

Group Supply Chain & Procurement Director

During FY 2024, we appointed a Supply Chain & Procurement Director. This is a new role, with the remit of developing our strategic approach to supply chain management, supporting the development of a strong and Aligned supply chain to enhance delivery performance and support the business’s future growth plans.

Our new director has been appointed as a Board member of the Supply Chain Sustainability School which will drive greater engagement with the School and help us leverage the learning and development and other resources within our own organisation, and across our supply chain.

Supplier onboarding

We have successfully upgraded our on-boarding platform. One of the major new additions to the platform is a Risk Radar which enables us to monitor live updates on a company’s.

- Financial health score.

- Event incident data from the Health and Safety Executive.

- Event incident data from the Environment Agency.

- Information held by the UK Employment Tribunal.

- Tax case information.

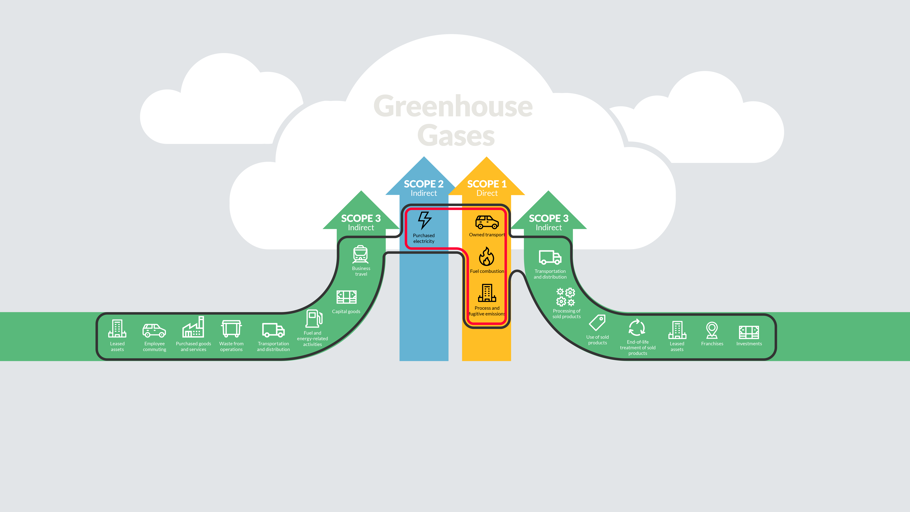

Net Zero Partners

We continue to engage with our supply chain through our Net Zero Partners initiative to support and learn from our wider supply chain to accelerate our own net zero journey and that of the wider industry. We have undertaken regional supply chain and client engagement sessions, project specific opportunity workshops and one to- one discussions with our major suppliers. We are also participating in industry-wide events and working groups to play our part in driving the industry towards a net zero future. Examples of tangible carbon benefits delivered through greater engagement with our supply chain partners include:

Wernick Hire

We have been trialling their GreenSpace ECO cabin which has achieved an A rated energy performance. The cabin combines smart sockets, battery energy storage, solar panels and enhanced draft sealing. Based on a canteen, two changing rooms, an office and meeting room/office this has provided us with energy savings of 466,000 kWh and a carbon saving of 85,000 kg CO2e.

Ainscough

We have continued to work closely with Ainscough Crane Hire not only for their exemplary approach to health and safety but also their ability to run their fleet of mobile cranes on Hydrotreated Vegetable Oil. This has assisted the business to reduce emissions and saved circa 69,000kg of CO2e during our last financial year.